The Premier Aluminum Llc PDFs

Table of ContentsOur Premier Aluminum Llc PDFsThe Definitive Guide for Premier Aluminum LlcNot known Facts About Premier Aluminum LlcThe Single Strategy To Use For Premier Aluminum LlcThe 9-Minute Rule for Premier Aluminum Llc

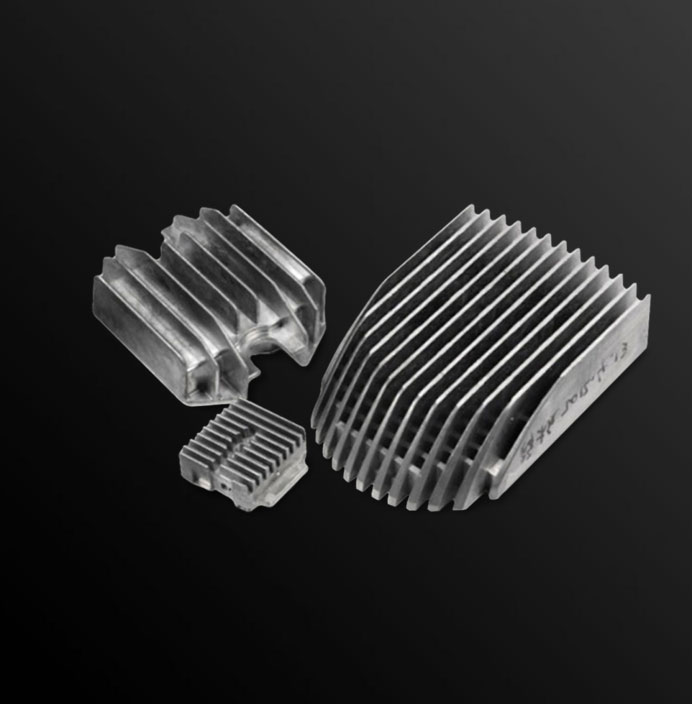

When choosing an aluminum foundry for your production requirements, it's critical to examine a number of aspects. One of one of the most crucial aspects to think about is the experience and skills of the factory. Choosing a shop that has the best expertise of the light weight aluminum casting procedure, and the profile to reveal for it, aids to have an effective outcome for your job.Having the experience and industry understanding to engineer your spreadings for optimal manufacturing and top quality outcomes will streamline the job. Producing light weight aluminum castings requires a complicated set of procedures to attain the ideal results. When picking a brand-new aluminum factory to companion with, guarantee they have comprehensive industry experience and are well-informed about all facets of the light weight aluminum casting process: design, manufacturing, material analysis, and product testing.

The foundry ought to also have a tried and tested track record of supplying remarkable items that fulfill or go beyond customer assumptions. Quality control needs to additionally be at the top of your listing when selecting an aluminum factory. By functioning with a certified foundry who complies with the standards for high quality control, you can shield the integrity of your item and ensure it satisfies your requirements.

Not known Details About Premier Aluminum Llc

Numerous components that really complicated shapes can be made utilizing this process. Before you start looking for a reliable light weight aluminum pass away caster, there are some important points that you require to do.

You have to ask on your own what type of light weight aluminum pass away castings you call for. After determining what you call for, you have to state the requirements of the aluminum pass away castings you require.

Do you know exactly how much cash you have to invest in the products? In order to do this, the finest point to do is to identify the number of light weight aluminum diecasts you call for. After having this information, you can begin looking into aluminum die-casting producers. You can do this by merely inputting the keyword phrase" Light weight aluminum die casting makers" on the Google search engine.

Some of the concerns you need to ask yourself are whether they have experienced and well-trained operators, exactly how long their service has actually been in operation, or if they have some achievements. You can typically get the response to these concerns from the maker's internet site. You can look into various other web sites or exterior resources to confirm if the info supplied on the maker's web site is genuine.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Another point you have to consider is the manufacturer's capacity to create aluminum die-casting items. Simply put, the quantity of products the maker can produce at an offered time. Several of the vital questions you require to ask yourself are whether the supplier can create a greater volume or can the manufacturer satisfy your demands.

(https://replit.com/@garymartin53403)Suppose your business needs 10,000 items of particular device parts from the maker within one month? You got this amount; nonetheless, the supplier can just create 5000 pieces of these maker parts within one month (Aluminum Casting company). Because of this, you will not have the ability to get the quantity that you get in a timely manner

The 5-Second Trick For Premier Aluminum Llc

Hence, it is important that you need to make inquiries if the manufacturer is executing an in-house tooling procedure. In addition, you need to ask the producer just how much the expense of in-house tooling is. Remember that the in-house tooling process, which allows you to produce distinctive layouts and shapes can be an additional cost.

This element straight correlates with the producer's manufacturing capacity. Aluminum Castings. You have to look for a manufacturer that can make sure quicker delivery of products.

This indicates that there are see page several choices that you can pick from. Today, customer demands keep on altering. It seems that clients are looking for an excellent combination of high quality, cost-effectiveness, and resilience. That is why it is considerably advised that you should select a producer that can create different sorts of light weight aluminum die-cast items.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Most frequently, these light weight aluminum die-casting products will certainly need some designs, machining, or finishing touches. Having this in mind, you need to try to find a producer that can execute a selection of additional finishing jobs once pass away casting is done. Some instances of completing procedures consist of Chromating, CNC Machining, Sandblasting, Powder finishing, Anodized, E-coating, Damp painting, Plating, and many even more.

Die spreading is one of the most affordable, exact, and protean manufacturing procedures in the globe moment. The procedure involves fitting molten significance, under stress, into a relevant die (earth), and previously strengthened it can be ejected and ended up (if necessary) in a range of means.